Dynamic hygrothermal simulation and full-scale validation of a structural insulated panel made from bio-based materials.

Given the environmental impact of the construction sector- responsible for 40% of the total primary energy consumption of the European Union- reducing both the embodied energy of materials at manufacturing stage and minimising operational energy consumption in buildings are urgent tasks.

Dynamic hygrothermal simulation and full-scale validation of a structural insulated panel made from bio-based materials.

Given the environmental impact of the construction sector- responsible for 40% of the total primary energy consumption of the European Union- reducing both the embodied energy of materials at manufacturing stage and minimising operational energy consumption in buildings are urgent tasks. Timber, agricultural residues, and bio-based materials are local renewable resources that can be transformed into buildings products and components, fomenting the creation of circular economies, and reducing the environmental impact of the sector. The objective of the European ISOBIO project, that ran from 2015 to 2019, financed under the Horizon2020 program, was to address these problems through the development of new insulating materials and renders from plant fibres, agricultural residues, and bio-based binders. The article presents the results of dynamic hygrothermal simulations and full-scale validation of a structural insulated panel made from bio-based materials, for use in the construction of nearly-zero energy buildings.

ISOBIO structural insulated panel for new buildings

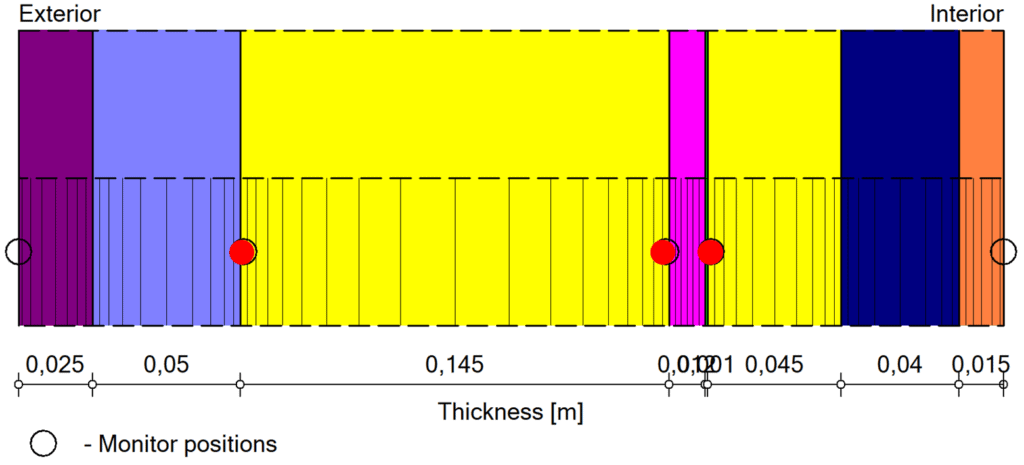

The prototype panel measured 1.95m x 1.95m, with a total thickness of 33.2cm in 8 layers with 9 different materials (Figure 1). The panel was rendered external with 25mm of lime and hemp plaster, applied on a rigid 50mm hemp insulation board, mechanically fixed to a 145mm red pine timber structure, filled with hemp, cotton, and flax insulation, followed by a 12mm OSB 3 timber board. An airtight and dynamic vapour control membrane was fixed to the inner face of the OSB, followed by a 45mm service void, insulated between timber battens with hemp, cotton, and flax insulation. The battens were positioned at 90º in relation to the main structural joists to reduce the thermal bridging through the timber. The inner service void was lined with a 40mm thermo-compressed straw board, plastered on the inside with 15mm of composite clay-hemp plaster, applied in 3 layers.

Test set-up

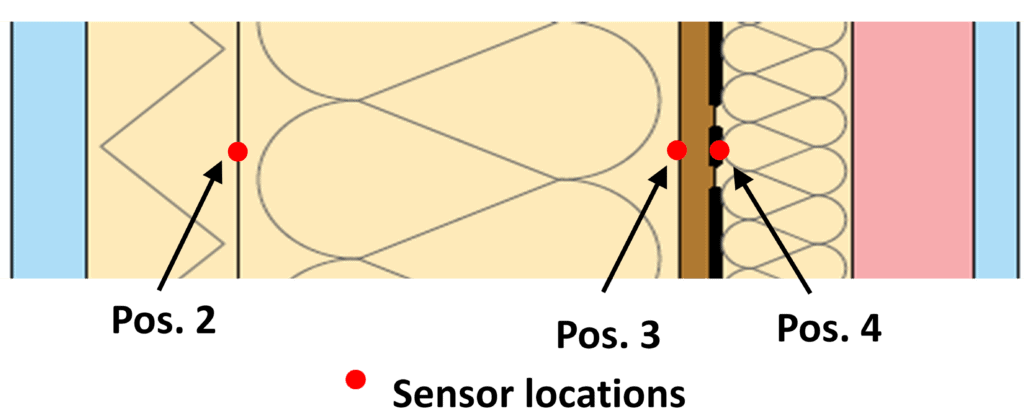

Figure 3 shows the installation of the panels in the demonstrator in Wroughton, UK. A monitoring system was installed, with a meteorological station recording external climate conditions: dry air temperature, relative humidity, solar radiation, wind speed, wind direction, rainfall, and barometric pressure. A temperature probe was installed on the outside of the panel, with a heat flow and temperature probe on the inner face, for measuring thermal transmittance in accordance with ISO 9869 [1]. In addition, temperature and relative humidity sensors were installed at 3 positions within the panel (Figure 2), to measure transient hygrothermal behaviour inside the panel and compare the results with dynamic hygrothermal simulations made with the WUFI Pro tool, following EN 15026 [2]. WUFI Pro 1D is a tool developed by the Fraunhofer Institute in Germany for assessing the hygrothermal performance of one-dimensional building envelope cross-sections, taking into account the moisture content of the materials, their transient hygrothermal performance, capillary transport and summer condensation, with hourly outdoor climate conditions. The software version used was WUFI Pro v. 6.2.1.2210

Data was measured at an interval of 5 minutes, from 24/02/2018 to 14/03/2018 in the HIVE demonstrator, UK, for a total 432 hours, or 18 days, with 5184 data points. The interior temperature was maintained at an average of 25.5 °C throughout the period, with the use of an electric convection heater.

Monitoring Results and Validation

Figure 4 shows a cross section of the modelled panel, with sensor locations. Figure 5 shows the WUFI model of the panel and corresponding sensor locations.

Figure 6 shows measured and modelled temperature and RH at position 2 (between the CAVAC rigid insulation and Biofib Trio insulation). Temperature dynamics are well reflected in the model. RH dynamics are less well reflected.

Figure 7 shows the measured and modelled temperature at position 3 (between the Biofib Trio insulation and OSB board). Temperature dynamics are well reflected in the model, with RH less so. The model nonetheless shows very close alignment with measured results.

Figure 8 shows the measured and modelled temperature and RH at position 4 (between the Intello membrane and the Biofib Trio insulation). Temperature and RH dynamics are well reflected in the model.

Figure 9 shows the measured average heat flow rate, compared with the WUFI modelled heat flow rate, showing very good agreement.

Conclusion

The results of the measured and modelled temperature and RH show good correlation, with dynamic temperature variations accurately reflected in the model. The short-term variations in relative humidity are not reflected with the same precision in the WUFI modelling results, possibly due to the assumption that the equilibrium water content in the materials is instantaneous, where in reality, there is hysteresis [3]. The hourly measured and modelled thermal transmittance data show very good correlation, with a difference of only 4% over the monitoring period.

The results indicate that bio-based materials combined in a composite SIP panel of this type can offer predictable hygrothermal performance for use in nearly-zero energy buildings.

References

- ISO 9869-1:2014 Thermal Insulation – Building elements – in-situ measurement of thermal resistance and thermal transmittance. (Aislamiento térmica – elementos constructivos – medición in-situ de la resistencia térmica y transmitancia térmica)

- UNE-EN 15026:2007, Comportamiento higrotérmico de componentes de edificios y elementos constructivos. Evaluación de la transferencia de humedad mediante simulación numérica.(Ratificada por AENOR en junio de 2010.)

- N. Reuge, F. Collet, S. Pretot, S. Moisette, M. Bart, O. Style, A. Shea, C. Lanos 2019, Hygrothermal transfers through a bio-based multilayered ISOBIO wall – Part I: Validation of a local kinetics model of sorption and simulations of the HIVE demonstrator. Laboratoire de Génie Civil et Génie Mécanique, Axe Ecomatériaux pour la construction, Université de Rennes, 3 rue du Clos Courtel, BP 90422, 35704 Rennes, France.