Terrassa Haus: Passivhaus Living in the heart of Catalonia

Terrassa Haus not only showcases the feasibility of Passivhaus principles in multi-residential developments but also demonstrates the economic viability of sustainable building practices. By prioritizing energy efficiency and environmental sustainability, Terrassa Haus offers residents a comfortable, healthy living environment while significantly reducing their carbon footprint.

Terrassa Haus: Passivhaus Living in the heart of Catalonia

Terrassa Haus offers residents a comfortable, healthy living environment while significantly reducing their carbon footprint.

Terrassa Haus is a testament to energy efficiency and sustainability, being the first multi-residential building in Catalonia to achieve Passivhaus Classic certification.

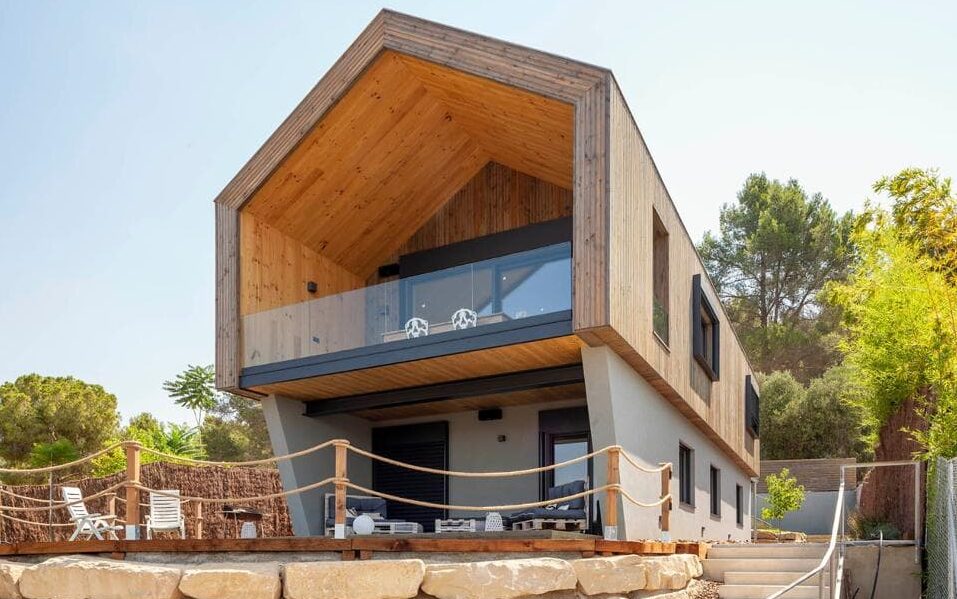

In the bustling city of Terrassa, Catalonia, Spain, an innovative residential development is redefining sustainable living. Terrassa Haus is the first multi-residential building in the city to achieve Passivhaus certification, setting a new standard for energy efficiency and environmental consciousness in the region. Developed by Cambolico and designed by architects Antoni Espona & Xavier Torcal, with Passivhaus consultancy, HVAC design, and Blower Door testing conducted by Oliver Style and Bega Clavero from Praxis Resilient Buildings, the project represents a bold step towards a greener future.

Commitment to energy efficiency and sustainability

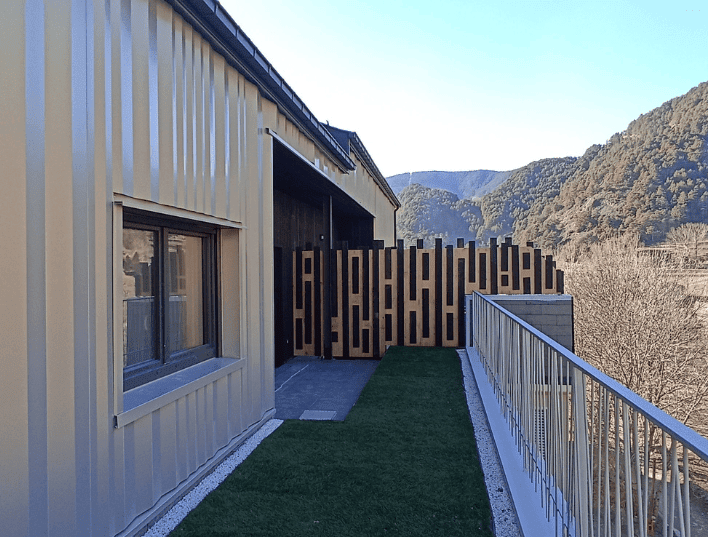

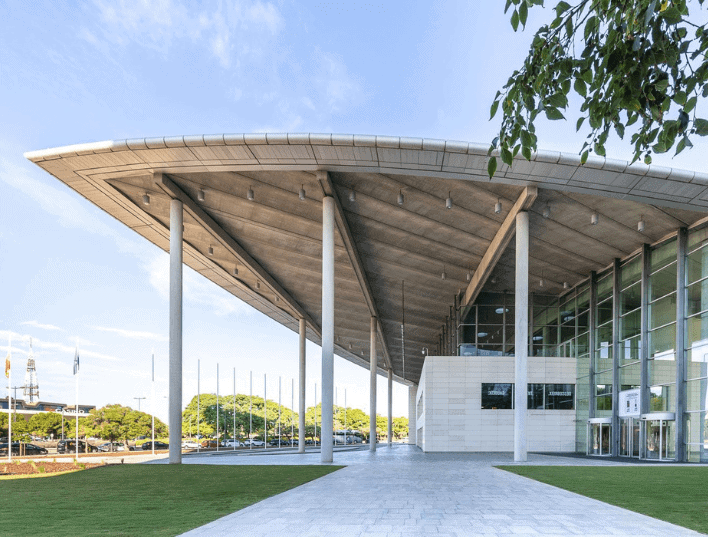

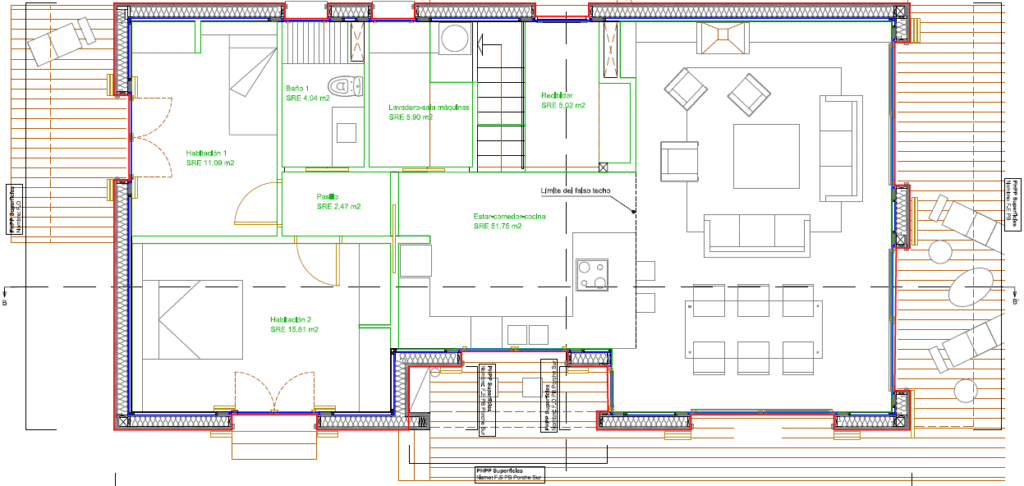

At first glance, Terrassa Haus blends modern design with eco-friendly features. The building comprises four floors, including ground-level commercial spaces and three floors of thoughtfully designed apartments ranging from 76 m2 to 154 m2. With a total floor area of 1142m2, the development offers residents a range of amenities, including a communal co-working space, bike room, gym, and a communal pool.

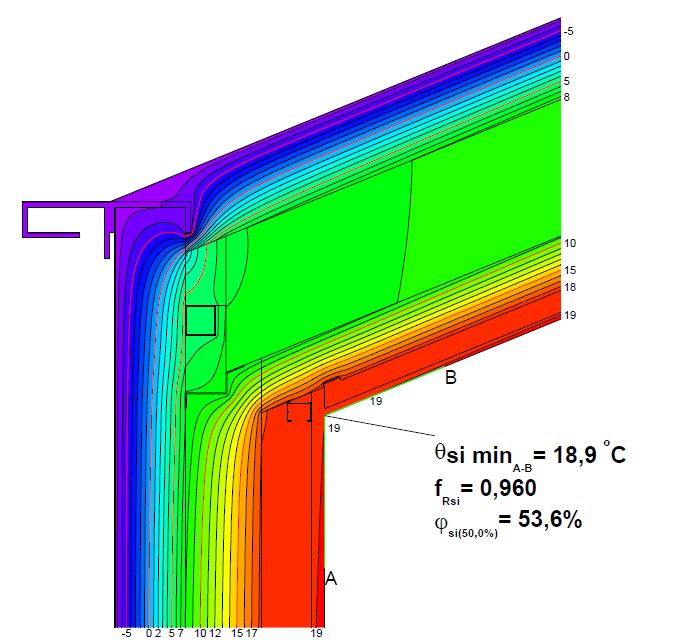

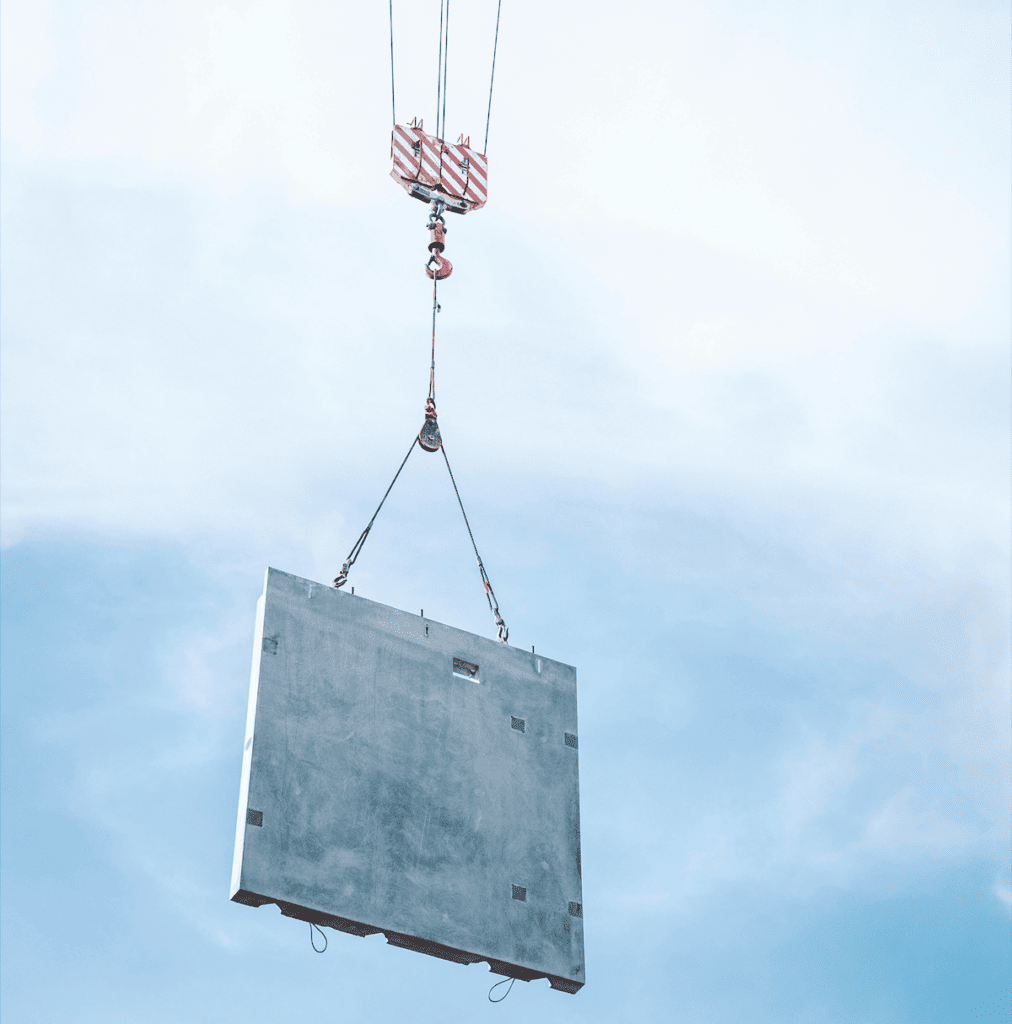

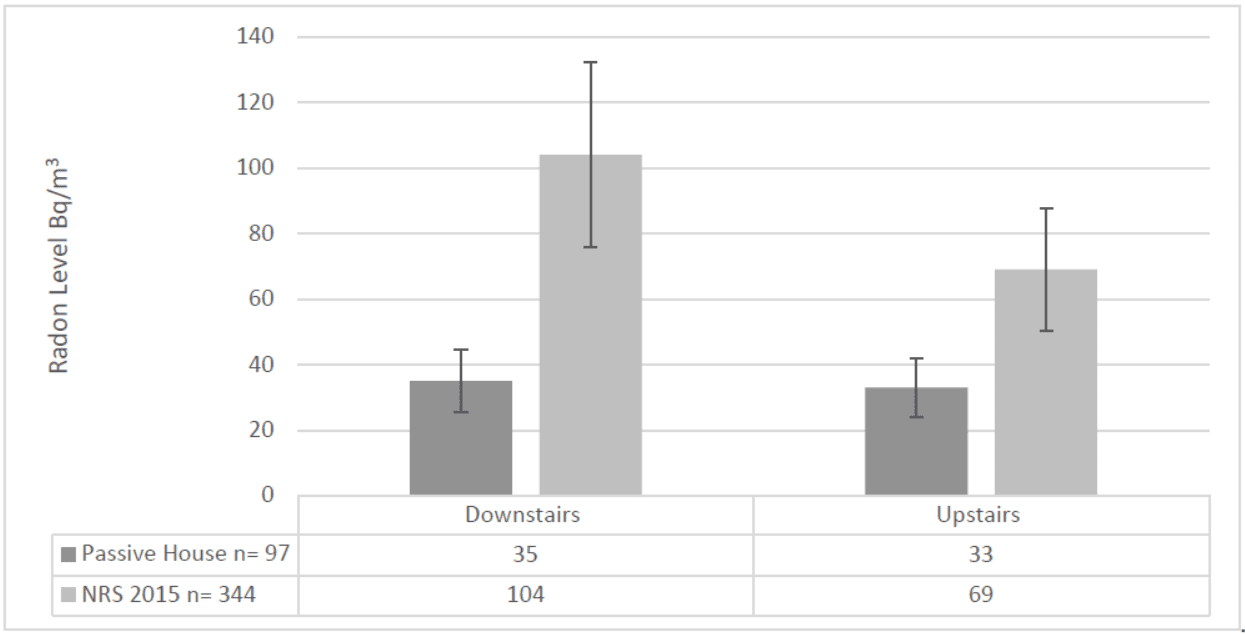

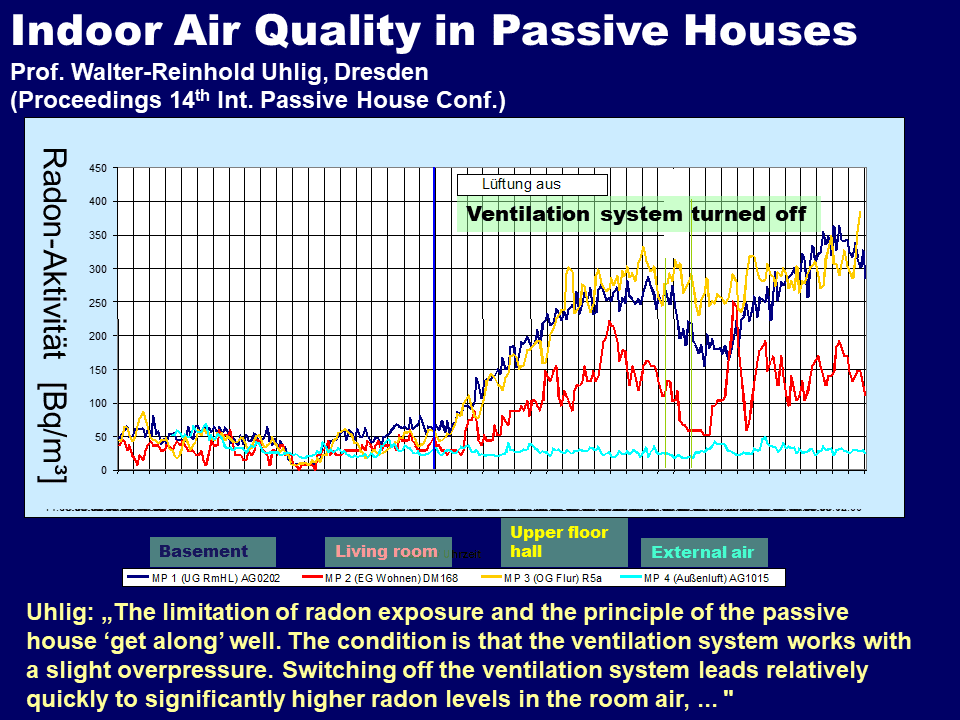

What truly sets Terrassa Haus apart, however, is its commitment to energy efficiency and sustainability. Built upon an existing concrete structure abandoned during the economic crisis of 2007, the building underwent a comprehensive retrofitting process to achieve Passivhaus certification. An external thermal insulation system with EPS insulation was meticulously applied over ceramic brick, supplemented by an additional layer of Knauf Insulation mineral wool in the service void, chosen specifically because it incorporates a bio-based E-Technology binder, free from added phenols and formaldehydes, protecting both the workers on site and future occupants from harmful emissions.. The roof is insulated with XPS insulation, ensuring maximum thermal performance throughout the building envelope. With an impressive n50 value of 0.6 air changes per hour, Terrassa Haus passed the Blower Door airtightness test with flying colours, reaffirming its status as a beacon of environmental responsibility and cutting-edge construction practices.

The attention to detail extends to the windows, heating, cooling, and hot water provision

The attention to detail extends to the windows, where Rehau PVC frames with argon-filled low-emissivity glazing were installed. Swisspacer insulated glazing spacers further enhance the windows’ energy efficiency, minimizing heat loss and maximizing natural light penetration.

For heating, cooling, and hot water provision, Terrassa Haus relies on individual Hitachi all-in-one heat pumps installed in each apartment. These state-of-the-art systems offer residents personalized climate control while minimizing energy consumption. Mechanical ventilation with heat recovery is achieved through individual Soler & Palau Passivhaus certified ventilation units, strategically positioned to draw in fresh air from the façade walls and extract stale air to the roof via shared ducts.

Terrassa Haus serves as an inspiring example of what can be achieved through innovation and collaboration

Terrassa Haus not only showcases the feasibility of Passivhaus principles in multi-residential developments but also demonstrates the economic viability of sustainable building practices. By prioritizing energy efficiency and environmental sustainability, Terrassa Haus offers residents a comfortable, healthy living environment while significantly reducing their carbon footprint.

As cities worldwide strive to combat climate change and promote sustainable development, projects like Terrassa Haus serve as inspiring examples of what can be achieved through innovation and collaboration. By embracing Passivhaus standards, developers, architects, and building professionals can pave the way towards a greener, more sustainable future for generations to come. Terrassa Haus stands as a testament to the power of visionary thinking and a beacon of hope for sustainable urban living.

Photos: terrassahaus.com